Steel Foundations

From mine to metal, Reibus U is your definitive source for learning how steel is made. 40 free lessons created by industry experts. Start your steelmaster journey today!

From mine to metal, Reibus U is your definitive source for learning how steel is made. 40 free lessons created by industry experts. Start your steelmaster journey today!

This is a description. Edit it on Lessons > Modules > Steel Foundations

Ironmaking is the metallurgical process of converting iron ore, which is rich in iron oxide, to elemental iron, which is about 95% pure iron. Oxygen is removed from the iron oxide, most often using a blast furnace, but iron ore can also be directly reduced using a reactor and natural gas. The output of ironmaking can be liquid hot metal/pig iron, iron pellets, or cast iron ingots.

OPEN CHAPTER TO READ MORESteelmaking is the metallurgical process of converting iron, which is high in carbon and impurities, into crude steel, which has less than 2.0% carbon and minimal impurities. The two main methods to make steel use a basic oxygen furnace (BOF), or an electric arc furnace (EAF).

OPEN CHAPTER TO READ MORESteel Casting is the metallurgical process of solidifying molten steel or other metals into a solid pre-determined shape and size, using controlled cooling. Semi-finished cast products will be further processed by rolling mills, forging processes, or machining. Cast products can include ingots, thick slabs, thin slabs, cast strip, billets, blooms, or near-net shapes, such as I-beams.

OPEN CHAPTER TO READ MORESecondary refining is a set of metallurgical processes performed after the Electric Arc Furnace (EAF) or Basic Oxygen Furnace (BOF) process. Secondary refining processes take place in the ladle but at a separate station, with the main purpose of relieving the primary steelmaking processes of these additional functions. Secondary steelmaking processes make bulk and fine chemistry adjustments for reducing sulfur, phosphorus, and oxygen as well as precise carbon and alloying additions, to ensure the steel meets specific requirements.

OPEN CHAPTER TO READ MOREShaping of steel into a final commercial product, either flat products, like coils or plates, or long products, like rail or pipe, is accomplished using different forming processes, such as rolling or forging, of the corresponding semi-finished cast products. Steel products can be created with many different microstructures and properties derived from various forming processes, heat treatments, and surface treatments.

OPEN CHAPTER TO READ MOREYou guys really have thought of everything, it’s like you've been listening in on our senior management meetings. Solving supply chain problems is our biggest challenge. That's what you guys do.VP of Sourcing Billion Dollar OEM

I love how I no longer need to chase people, your platform and your people do it for me. Let me know how I can help you as you keep developing your site.”VP of Procurement National Service Center

I cannot see a reason in the world why we wouldn’t use your system, it’s the way the world is going. I have been telling people for the last 20 years the Steel industry needs to modernize.Owner & President National Service Center

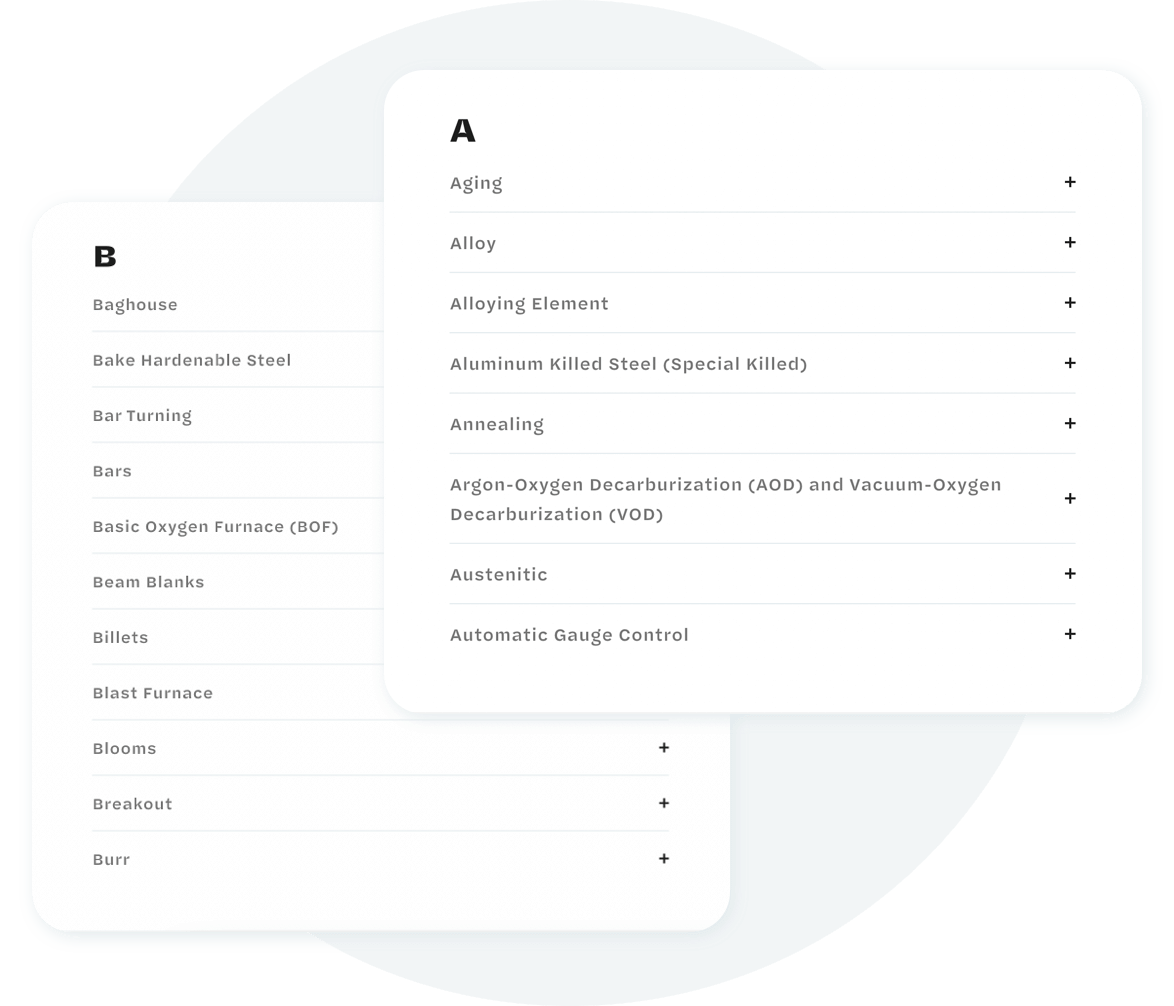

The steel & metals industry has been around for decades, and the terminology used can be very specific. In order to serve our community better and increase accessibility, we are thrilled to offer a glossary of these terms for your convenience.

View Glossary

Industrial metal gauge charts for carbon, stainless steel, and aluminum.

Metal Gauge ChartsMetal coil color charts for roofing, siding and more – from various manufacturers in the steel industry.

Metal Color ChartsCalculate the lineal feet of a coil based on thickness, width, and weight.

Calculators