How Steel is Recycled Steel Foundations

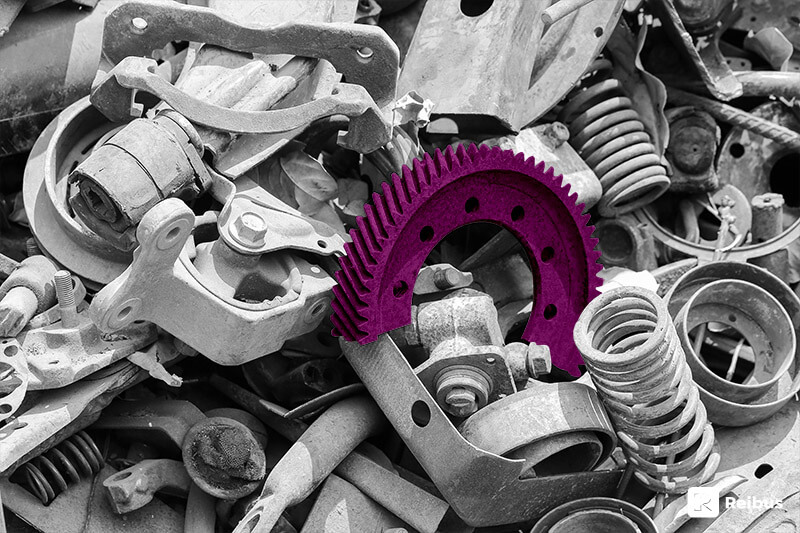

Steel scrap consists of recyclable steel materials left over from product manufacturing as well as consumer use. It can include materials like parts of used vehicles, building supplies, production scrap, and surplus materials. Unlike other waste, steel scrap is an important industrial commodity that can have significant monetary value. It is required for both the Basic Oxygen Furnace (BOF) and Electric Arc Furnace (EAF) processes of steelmaking.

Steel scrap is bought and sold based on its classification. It is generally classified into various types, based on its source, shape/size, chemical makeup, metallurgical properties, level of purity, or other attributes.

According to research conducted by the U.S. Environmental Protection Agency, recycling scrap metals is beneficial to the environment. Using recycled scrap metal in place of virgin iron ore can save significant amounts of energy, raw materials, air pollution, water, water pollution and mining wastes.

As an example, for every 2,000 pounds (910 kg) of new steel produced from scrap steel, these raw materials are conserved:

- 2,500 pounds (1,115 kg) of iron ore

- 1,400 pounds (625 kg) of coal

- 120 pounds (53 kg) of limestone

Recycling steel and iron scrap back into liquid steel is a fundamental production goal of the steel industry.